Eliminate islands of automation with the CORS warehouse execution system.

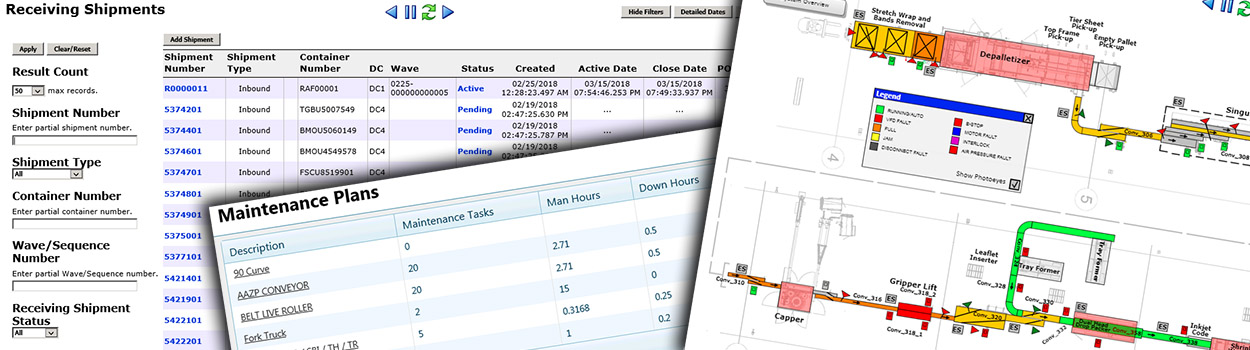

The Compass Order Routing System (CORS) software package ties a warehouse management system (WMS) to a programmable logic controller (PLC). This gives facility managers a fine level of customization and control over the operations of all automation equipment systems. This advanced technology displays control information in real-time and sends visual notifications of any system faults instantaneously.

Through CORS’ sleek design, users can view control information, control package flow, and conveyor/sorter diagnostics, along with other critical data. Analysis is catered to the unique needs of a specific industrial warehouse, providing detailed error logs and reports to assist in diagnosing any possible control failures. This software can be deployed in a comprehensive web based package. Additionally, for technical support, Compass Engineering can remotely connect into a system at any time to walk through any problems the infrastructure may be experiencing to get the system back up as quickly as possible.

What does CORS offer?

This unique web client provides a broad gamut of capabilities and features. All of these attributes are dealt with carefully and tested thoroughly before distribution to guarantee the highest level of quality in our projects. The following are the main components of our sophisticated CORS package:

- Security – Each installation site owner can create individual user accounts, allowing the system administrator to delegate certain rights to specific users and groups with fine granularity of control.

- Portability – The CORS interface runs on most modern browsers. There is no extra software to install. A manager or maintenance worker can access CORS from any computer system connected to the system’s network, or even from home with the use of virtual private networks (VPNs).

- Reliability – CORS utilizes Microsoft technology, a proven, reliable architecture used by most of the largest Fortune 500 companies.

- Customization – CORS can be customized either by Compass Engineering’s software engineers, or by the on-site IT department. CORS is implemented using popular application software that many developers already have experience with.

- Openness – Compass can provide source code to customers who meet specific conditions. The open source approach enables complete control over control system customization.

- Speed – All data requests made by the client return up-to-the-second responses directly from the database controlling sortation.

Supported Technologies

Compass supports the use of Windows Server® as the application platform, and SQL Server® as the database management system for application data. The only requirement is an HTML5 compatible browser (such as Internet Explorer® or Mozilla Firefox®).

Previous versions of CORS have been built around different platforms such as Linux and QNX, but the industry standard has become a Microsoft Windows based solution. This product fits well within the typical customer environment and is easily maintained by the end user. Under most situations, CORS can operate in a Virtual Environment (VMWare) or a Microsoft Cluster. CORS is structured around Microsoft SQL Server (MSSQL) and is compatible with MSSQL 2008 / MSSQL 2008 / MSSQL 2008R2 / MSSQL 2012.

The CORS system is offered only by Compass Engineering in an effort to provide you with the utmost control for your systems. These various core functionalities are the cornerstones of our software package and ensure that you will be granted complete administrative authority over your system solutions.

CORS: Operational visibility of all material handling equipment, end-to-end.

Connect your users to DC-wide operations.

This gives them complete, simple, easily understandable, one-stop visibility into inventory, process and equipment status throughout your facility. Functions include continuous measurement and reporting of all key operations metrics; exception management and diagnostic tools; up-to-the-second graphical visibility into equipment status/performance; and comprehensive views of your inventory, with individual status and location by handling unit, wave or batch.

Connect your warehouse management system (WMS) to order fulfillment operations.

Even specialized and highly automated order processing can be accommodated, including auto-box or auto-bag order fulfillment, auto-label/print apply, packing list printing/inserting and more. These operations are directly supervised, optimized and controlled to fill both direct-to-consumer and retail store orders.

Connect your WMS to your unit sorter (tilt-tray, cross-belt, bombay and more).

The sorting algorithms that are unique to your business (no matter how complex) can be executed in real-time at high speeds for packing, shipping, returns or other fulfillment processes. Further, that inventory can be controlled with a very high degree of precision, with complete inventory accountability maintained at all levels and within each step of the fulfillment process. Our agility and affordability allows our customers to minimize the cost of loop sorter ownership.

Connect your automated storage and retrieval system (AS/RS) to your WMS, conveyors and sorters.

This optimizes storage and retrieval inventory to achieve balanced flow within the DC. It can also power wave/batch picking optimization and order fulfillment. Director WCS completely integrates a storage system intelligently into your DC operations.

Connect your WMS to receiving docks.

This enables inbound shipments to be fluidly unloaded, automatically checked-in and reconciled against advance shipping notices (ASNs), or blind receipts acknowledged as either purchase order (PO) or stock keeping unit (SKU) items with camera-based data entry. Received inventory is sorted/forwarded according to your specific processing requirements.

Connect your WMS and transportation management system (TMS) to your shipping docks.

This allows finished orders to be automatically identified, weighed, dimensioned and sorted based on your algorithms and freight optimization specifications. The system automatically verifies product at the docks, fluidly manifests it and loads it onto a trailer in one motion.